|

Cutting

EKSALbond can be cut with a vertical panel saw, circular or jig saw.

Use a standard guillotine for this purpose. Ensure the top cover sheet is inserted properly.

Carbide tipped (CT) saw blades

Blade geometry |

Tooth thickness approx. 2 - 4 mm, tapered to the inside to prevent jamming |

Tooth geometry |

Trapezoid tooth / flat tooth |

Clearance angle α |

15° |

Rake angle γ |

10° positive |

Maximum feed s |

20 m/min |

Pitch t |

10 - 12 mm |

|

|

Shearing

EKSALbond is easily sheared with a guillotine. Shearing will cause a slight deflection of the cut edge on the impact side.

To prevent damage to the cover sheet, use protective pads between down-holders and EKSAlbond surface. |

|

Punching

EKSALbond panels of any thickness can be punched using conventional sheet metal punching machines.

For clean cuts use sharp tools and dies with minimal cutting clearance (0.1 mm).

Punching will cause a slight deflection of the cut edge on the impact side.

Holes of a minimum diameter of 4 mm can be punched. The minimum width of web between hole edges is also 4 mm. |

|

Contour Cutting

EKSAlbond can be cut to shape using jig saws,CNC machining centres and water jet cutting machines.

Use jig saw blades for aluminium

Cut abrasively when using a water jet cutting machine.

Pre-drilling of the panels is necessary when starting the cut in the middle of a panel as it is not possible to drill through with the water jet.

For contour cutting on CNC machining centres use a one-edged cutter. |

|

Bending

Use a folding table.

Min inside radius r=15xt (t=panel thickness).

The minimum required radius is r = 10 x t (t = panel thickness)

The spring-back effect of EKSALbond is larger than that of a solid aluminium sheet

The die edges should be rounded and smooth

To prevent damage caused to the panel surface, the protective foil must not be removed during bending. |

|

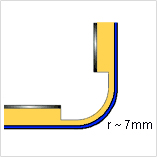

Roll Bending

EKSALbond can be bent using a roll bending machine (3 or 4 rollers). Make sure that the feeder does not exert too much pressure. Bending rollers which are also used for bending other metals must be thoroughly cleaned from swarf before forming of EKSALbond composite panels. Make sure to use only polished rollers free of dents and other defects.

To prevent damage caused to the panel surface, the protective peel-off foil must not be removed during bending. Additionally, the visible surface can be protected by using plastic pads of 1 - 2 mm thickness. |

|

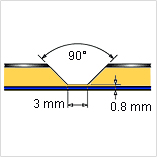

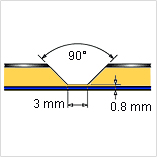

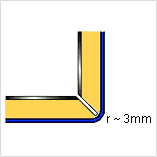

Routing & Folding

EKSALbond composite panels can be shaped using a very simple processing method.

The technique, called the routing and folding method, enables a fabricator to produce shapes of various kinds and sizes.

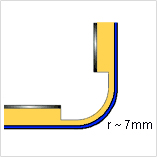

A V-shaped or rectangular groove is routed on the reverse side of the EKSALbond composite panel using a disk or end milling cutter. A thin layer of the core material should be left at the base of the groove, i.e. on the inside of the outer cover sheet. The untouched outer cover sheet can now be bent manually, giving an exact and clean folding line which follows the routed groove. The outer radius of the folded edge depends on the shape of the groove and its depth.

We recommend that the routing be done using a CNC machining centre.

The routing and folding method can be used for EKSALbond composite panels with all available standard surface finishes.

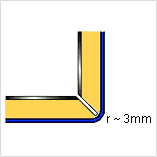

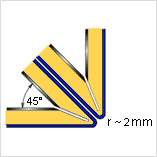

| 90° V-groove for folds up to 90° |

|

|

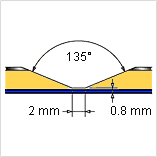

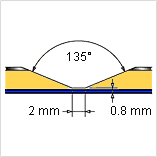

| 135° V-groove for folds up to 135° |

|

|

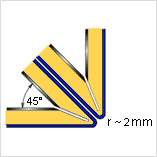

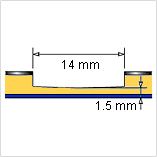

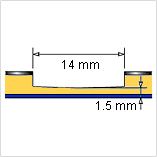

Rectangular groove for folds up to 150°, depending on panel thickness.

Not suitable for ALUBOND®A2. |

|

|

|

|

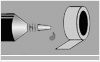

Drilling

EKSALbond is easily drilled- use bits designed for drilling aluminium for best results. |

|

Riveting

EKSALbond is easily drilled - use bits designed for drilling aluminium and aluminium rivets for best results. |

|

Screwing

Threaded fasteners for outdoor use

For outdoor use make sure to take the thermal expansion of the panel into account. To avoid jamming, the hole diameter in the panel must allow for the expansion.

Fastening without jamming is possible using fascia screws made of stainless steel with sealing washer (Fig. 1) that have been approved for construction. The screws must be suitable for the corresponding substructure (please note the information given by the manufacturer). The screws should be tightened with a torque wrench or screwdriver so that the sealing washer is placed on the panel for sealing the bore hole without exerting pressure to the panel.

Threaded fasteners for indoor use

Screws for sheet metal and wood with different head-shapes are suitable for indoor use (Fig. 2). They do not normally allow for any panel expansion. Countersunk screws can be inserted by the usual countersinking method or by depressing the aluminium surface into the panel. When depressing the aluminium surface, the hole diameter in the panel must be larger than the screw diameter. |

|

Bonding

Metal adhesives/Universal adhesives

For indoor use, trade fair/exhibition stand structures, machines, etc. most metal or universal adhesives are suitable.

Tapes/Velcro tapes

Double-sided tapes (such as the 3M-VHB high capacity jointing systems) can be used for the above applications with low tensile or transversal strength requirements.

Adhesive sealing compounds

For high-strength and elastic connections we recommend the following one-component adhesive sealing compound. |

|

Clamping

Any suitable connection or shock-resistant frame can easily be made with serrated aluminium sections. |